What is MFC?

Cellulose is the most abundant and renewable natural polymer on Earth.

Today at FiberLean, our process converts cellulose, sourced from wood fibres, into its primary constituent building blocks; fibrils.

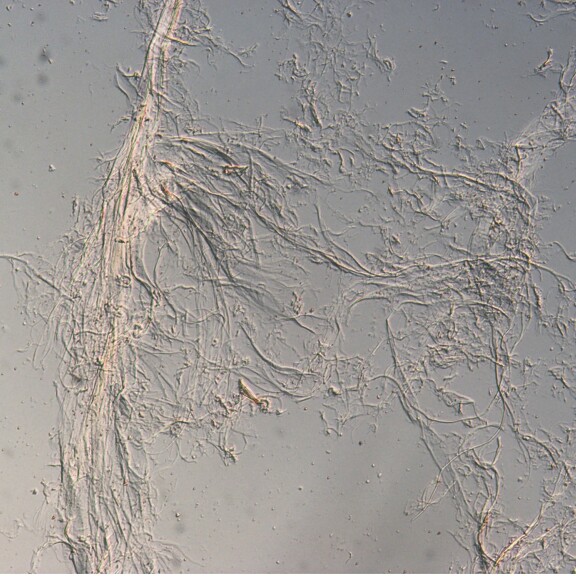

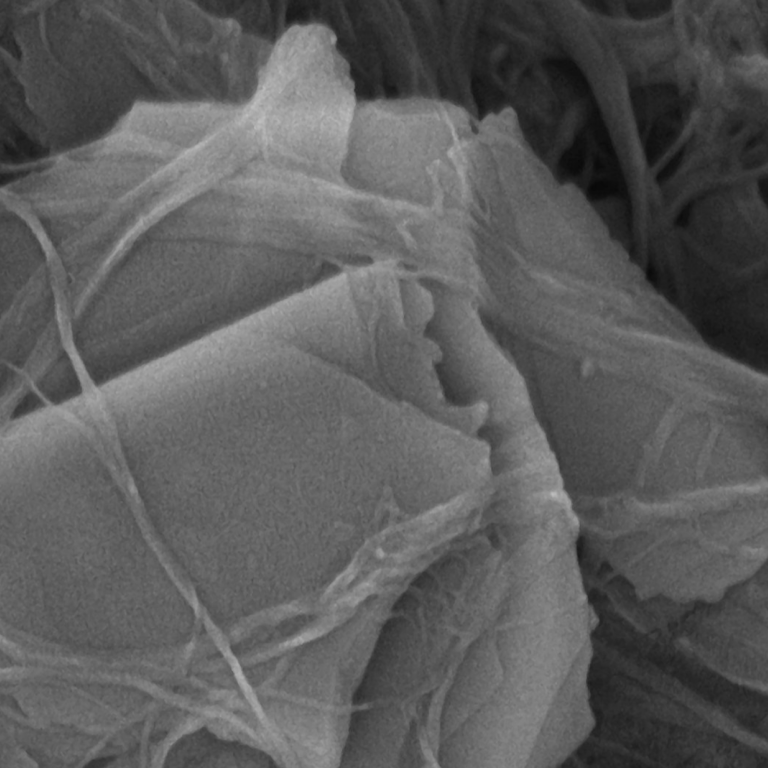

These fibrils are re-engineered at micro-scale to have a large aspect ratio and high surface area, yielding an interconnecting, dense, web-like network referred to as Microfibrillated Cellulose.

How it works

The MFC has a large surface area, thus allowing the formation of more hydrogen bonds within the web, giving natural strength to the material.

FiberLean MFC can be tailored to fit the specific customers' application needs with several fibre types alone or a composite with minerals.

MFC Benefits

Improved Properties

The increase in bond strength allows the reduction in refining or the use of bulkier pulps such as CTMP.

- Barrier properties

- Improve surface strength

- Improve printability

- Reduce porosity

- Improve web density

- Increase web consolidation

Raw Materials Reduction

MFC increases bonding, giving natural strength that allows you to reduce additives and expensive fibres or other materials.

FiberLean MFC provides the bonding and wet web strength permitting you to significantly increase the filler level in your paper.

Improved Process

The increased hydrogen bonding improves the initial wet strength of the web. This allows a smoother run on the paper machine, less web breaks for more productivity, with no additional additives required.

The use of MFC can decrease the energy required to refine fibres. You can replace your starch and strength additives with your in-house made MFC!

Develop New Products

Benefit from adding MFC directly into your feed to increase significantly the strength of your product, allowing improvements such as lightweighting.

Or use our patented FLoT MFC Jet Applicator to add a natural barrier surface to your product.

Our MFC is a runaway for innovation and allows you to expand your portfolio... All without additional CapEx.

MFC Products

MFC Formulations

No limits to formulation possibilities

- Your MFC recipes = your customised benefits

- Each plant comes with the capacity to use any cellulosic fibres to make the best MFC

- Looking for ultimate strength? Use our MFC made with virgin fibres

- Looking to save costs? Blend your MFC with cheaper materials like minerals

-

Your own customised recipe

-

Use all cellulosic fibres

-

Use recycled fibres

-

Blend with mineral or resins

-

Adjust MFC strength

Contact us

Collaboration is our way to create value. FiberLean is made up of engineers, paper mill professionals, scientists and individuals who care about our future.

Contact

Request for more information

To make an enquiry please complete the form below.